Do not bend the chain laterally.

For chain wrapped suspension, the following

table shall be used as the standards.

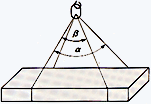

Make the angle of suspension as small as possible.

An angle β of more than 30° will result in sliding.

Strength efficiency of the suspended load's

angle (Table A)

| Suspension Angle α | Above 90° | 45° | 30° |

| Strength efficiency % | 60 | 50 | 45 |

strength efficiency (Table C)

| angre α | 30° | 45° | 60° | 90° | 120° |

| strength efficiency % | 96 | 92 | 86 | 70 | 50 |

Be careful to prevent the chain from being affected by heat. When the temperature is 400°-500° the impact energy value will be reduced by blue brittleness.

Efficiency of Working Loads in High-Temperature Operations (Table B) %

| Over -40°C and below 200°C | Over 200°C and below 300°C | Over 300°C and below 350°C | Over 350°C and below 400°C | Over 400°C and below 475°C | Exceeding 475°C | |

| M(4) | 100 | 100 | 85 | 75 | 50 | Do not use. |

| S(6) | 100 | 90 | 75 | 75 | Do not use. | |

| T(8) | 100 | 90 | 75 | 75 | Do not use. | |

- ・ If more than a single sling is used, put the weight of the load evenly.

- ・ Do not twist the chain.

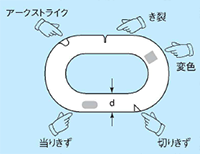

- ・ Do not conduct welding work while suspending a load or in a place where the chain could be earthed (arc strike is a cause of breakage)"

- ・ When cutting the chain, use a high-speed cutter in order to prevent heat effects (do not use gas cutting)

- ・ Conduct regular check-ups using the following standards.

Inspection and Disposal level

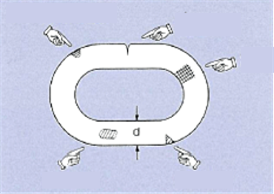

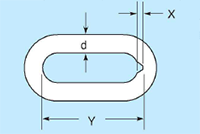

dn: Nominal diameter d: Curved diameter P: Pitch

| Inspection items | Disposal Standards | Repair and measures | |

|

Arkstrike | A small arc strike is a mortal wound | Abandon |

| Crack | As above | If the crack depth is less than depth dn x 0.05, use a grinder or file to smooth it. | |

| Scratch | Depth: welded part max.0.07dn Other parts max 0.1dn |

Same as crack | |

| Discoloration | prohibited | The discoloration is due to heat effect, so consider whether it is being used with the strength within the range of (Table B) | |

|

Bend | x=0.1dn | If bending or twisting occurs it is caused by overload, so upgrade the size of the chain to one suitable to the load. |

|

Twist | x=0.1dn | |

|

Wear | x=d-0.1dn | If it reaches the standard situation in a short period, it is caused by dust or overloading, so resolve it according to the cause. |

| Elongation | Y=1.05P | If the pitch of the link is elongated, it is a sign of overload. Please upgrade the size. | |

* The diameter(d) of the curved part is thinner than the nominal diameter (dn) for manufacturing reasons, but there is no quality problem and the break strength is satisfactory.

Drop in breaking load due to plating or painting

Plating

As a result of different plating temperature and tempering temperature or other factors, plated items sometimes weaken by about 15%. Plating of high-strength chains is a special task, so please contact us.

Painting

If break testing is carried out while paint or oil is stuck on the chain, the strength of chain may fall by a maximum of 8%.

(Breaking elongation of the chain will be reduced due to slipping on the breakage face due to the oil) Elimination of oil is compulsory as stated in the ISO test regulation.

During practical use, there will be no occurrence of such problems as the paint is peeled off during use.

* Breaking load values in our catalogue are those tested with unpainted products.

About Conveyor Chains

Notes

Painting

Do not use plating on chain and conveyor parts, as this will reduce their strength. Also, do not apply hot paint.

Also, depending on the rust prevention oil, it may reduce the breaking load, so do not use it.

Safety

- 2.1 Never inspect conveyor parts while the conveyor is running. Make sure it has stopped completely.

- 2.2 When inspecting conveyor parts, indicate on the equipment control panel that it is being inspected, and take appropriate measures to prevent erroneous operation.

- 2.3 Inspect conveyor parts on the return side rather than on the transport side as much as possible. When inspecting on the transport side, please pay sufficient attention to falling from the top.

- 2.4 When cutting the chain, use a cutting machine. The chain is heat treated. If the chain exposed to high temperatures, it may lose its heat treatment effect."

Link Chain Inspection and Disposal Standards

| Inspection items | Disposal Standards | Repair and measures | |

|

Arkstrike | Small arcstrike is a mortal wound | Please remove waste spattering. |

| Crack | As above | Do not use. | |

| Scratch | Depth welding part max.0.07dn others max 0.1dn |

Same as crack | |

| Discoloration | prohibited | Do not use if the color has changed (grey or deep blue) due to heat, as the strength has reduced. | |

| Corrosion | Severe corrosion | Do not use if there is significant corrosion or pitting | |

|

Wear | Parallel part Max.0.1d Curved part Max. 0.15d |

Do not use the chain with a straight part that is 10% or more thinner, or a curved part that is 15% or more thinner. |

| Elongation | Y=max.1.05P | Please do not use if the links have elongated more than 5% of the specified length. | |

* The above values are reference values only, and the conditions differ depending on each conveyor device, so please refer to them as necessary.

Specifications are subject to change without notice for improvement. Thank you for your understanding.

* We strictly prohibit the sale or use of our products in North America and Europe.