Chainwall

Patent Title 'Reinforced soil walls'

Patent No. 3883551,4455966

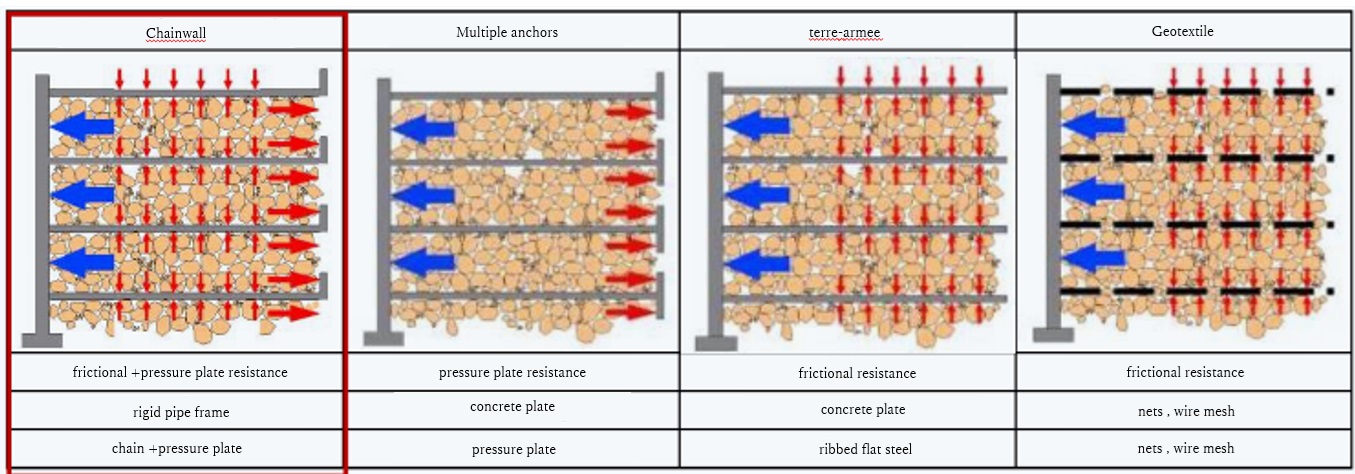

Concept of Chainwall

Reinforced Earth, Geotextile

Type in which the wall material is supported by the frictional force of the reinforcement.

Multiple anchors

A method in which the wall material is supported by the resisting force of the support plates.

Chainwall method

A method in which the wall material is supported by both the frictional resistance of the chain and the pressure plate resistance.

Features of the Chainwall

(1)High-strength structure

- - Large pull-out resistance of the chain

- - Structure that can withstand the settlement of the embankment

- - Walls that can withstand the rolling compaction load during construction

(2)Excellent workability

- - Lightweight

- - Boltless joints on the walls

- - No need for concrete

(3)Good cost performance

- - Highly rigid and low-cost walls

- - Can use soil generated on site.

- -No need for temporary roads for bringing in components

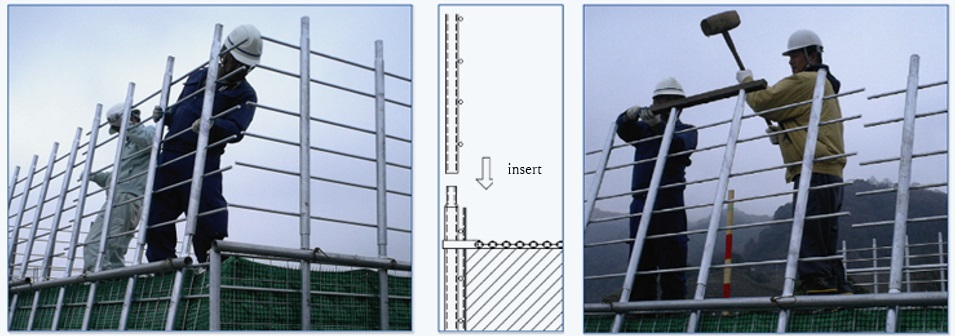

Ease of pipe frame installation.

Pipe frames can be jointed simply by inserting them (boltless), so no special tools are required. Lightweight (32 kg/sheet), enabling manual installation.

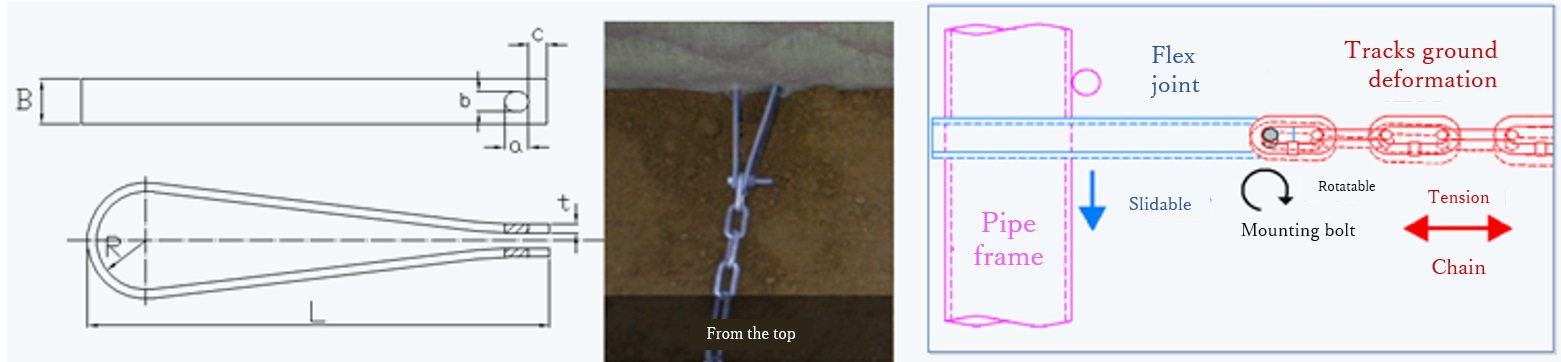

Structural properties of flex joints.

- - Flex joints connect wall and reinforcement materials.

- - Highly resistant to axial tensile forces and free to rotate in other directions, but effective in tension against earth pressure.

- - Flex joints can follow the settlement of ground.

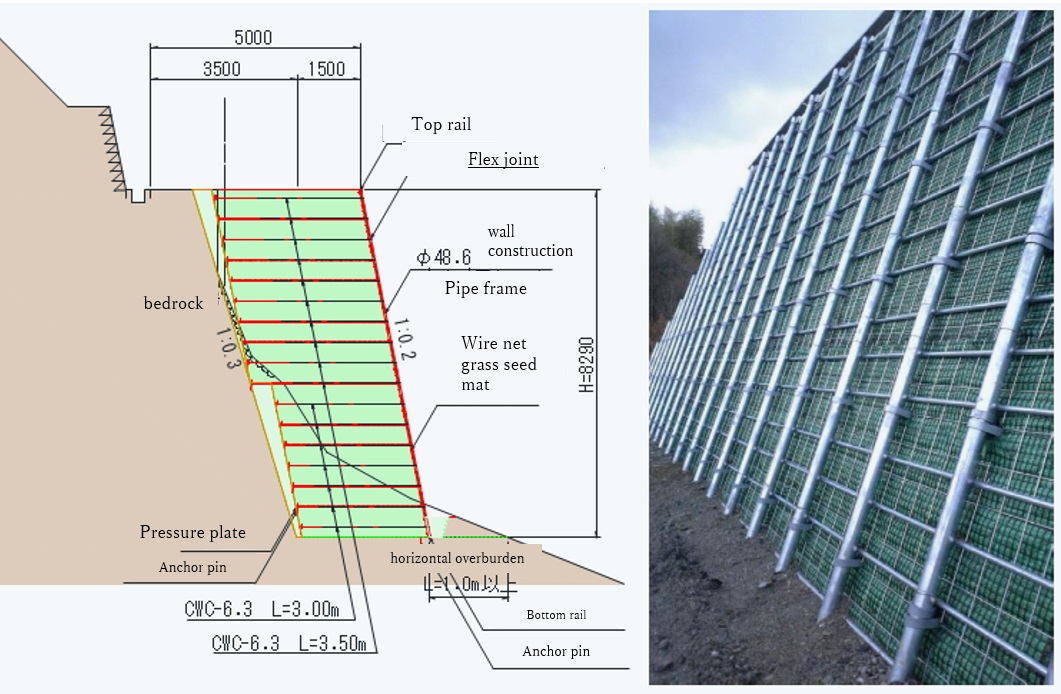

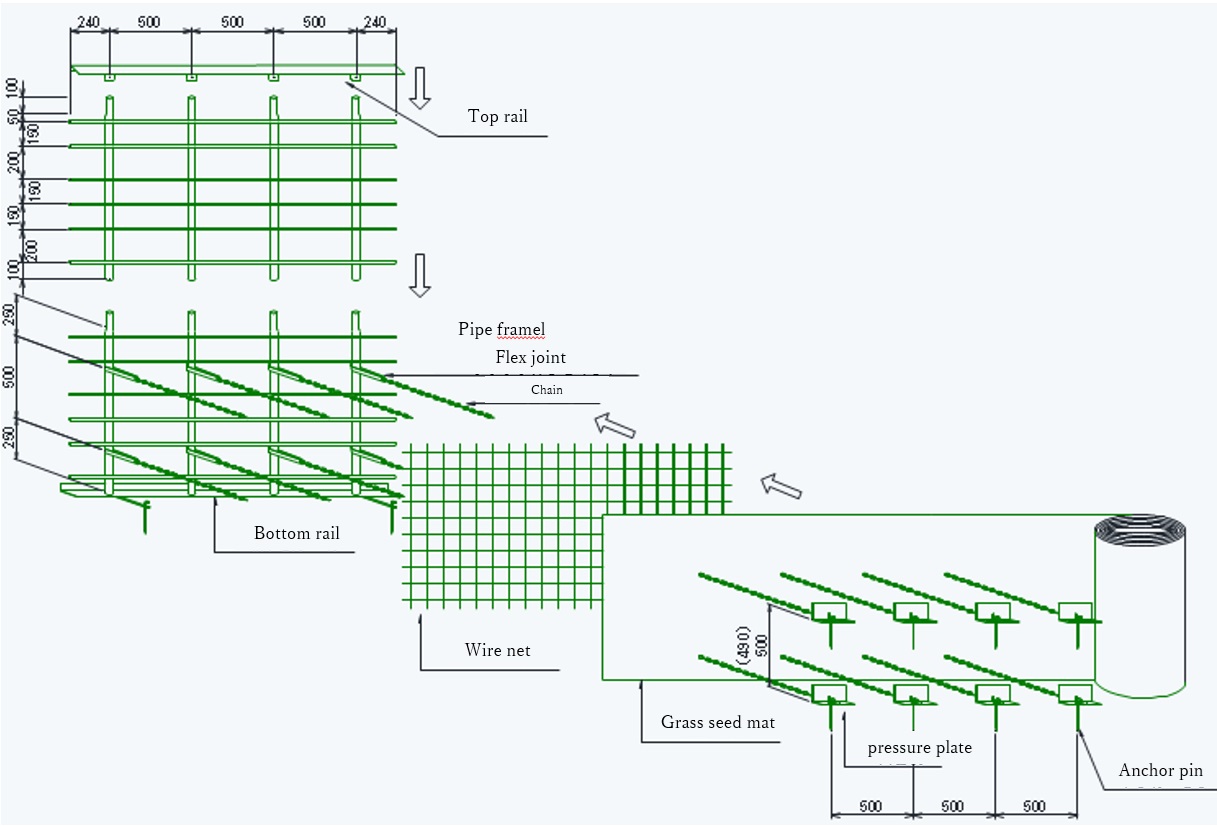

Standard cross-section of Chainwall

Components of the Chainwall

Chainwall construction procedure

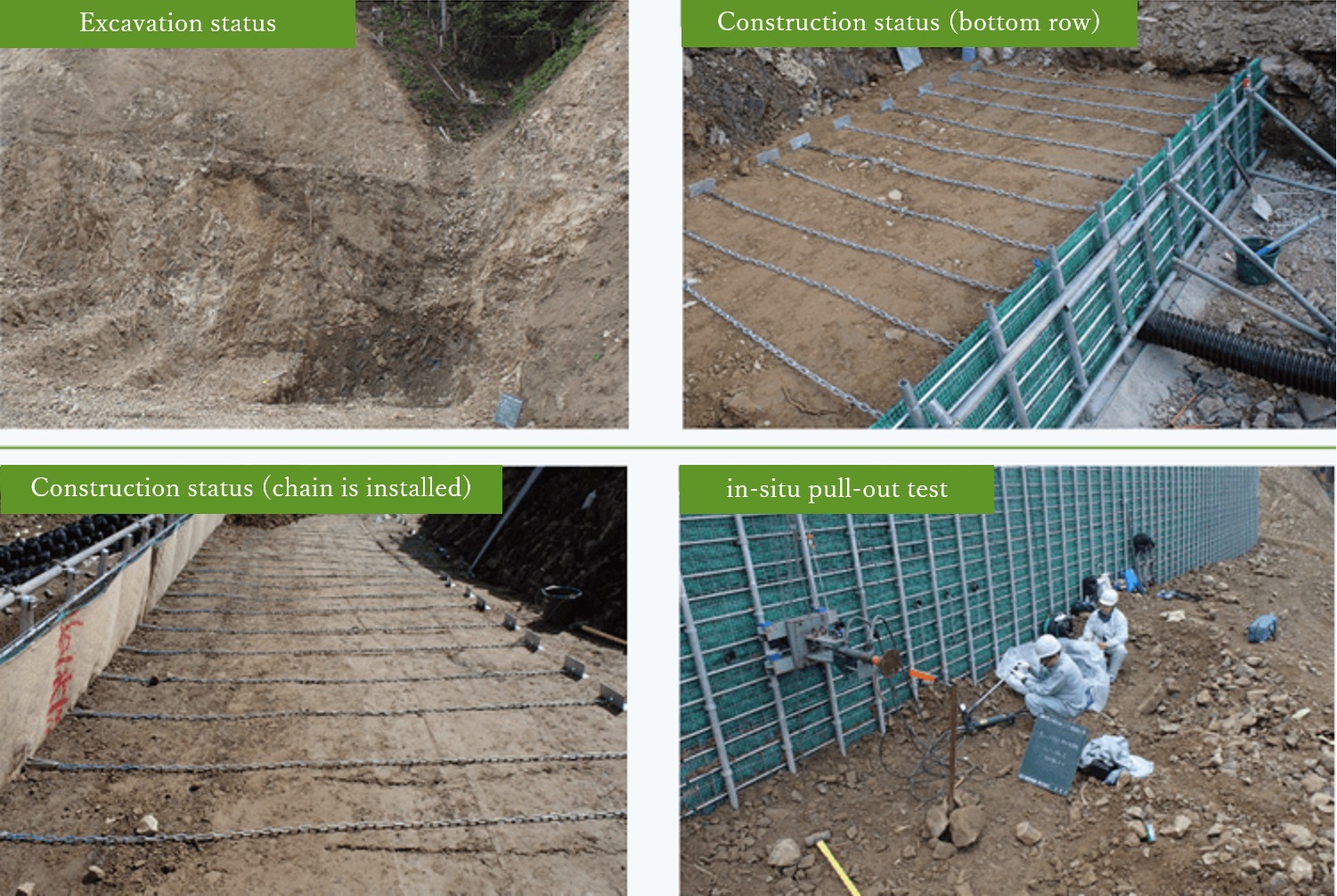

1.Excavation, foundation work (e.g. sand foundation) and bottom rail installation

- - Install bottom rail on the foundation ground after levelling the base surface.

- - Anchor pins are driven in and fixed in place

2.Installation of bottom pipe frame

- - The bottom rail has a projection that matches the slope of the wall, so the pipe frame is inserted and installed.

3.Installation of shoring

- - Pipe supports are installed to prevent the bottom pipe frame from falling forward.

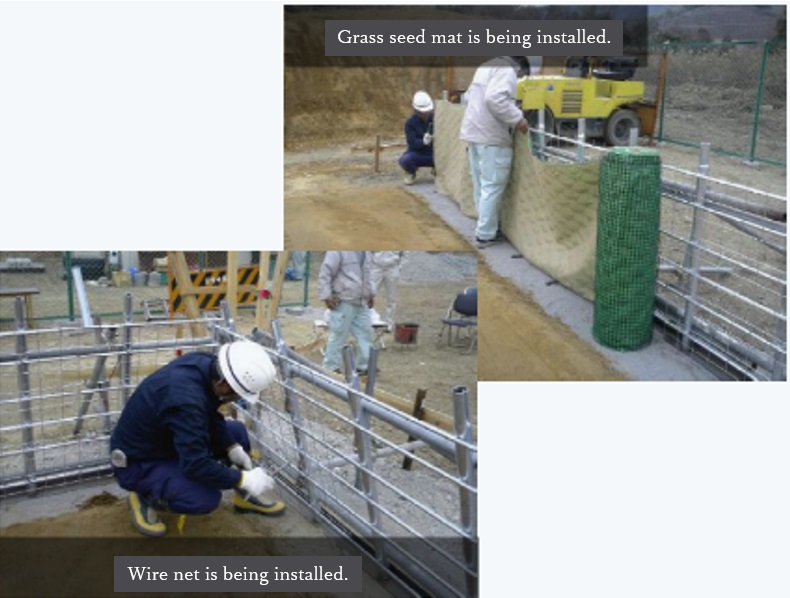

4.Installation of wire netting and vegetation mats

- - Wire nets and vegetation mats are attached using binding wire.

- - The wire netting is on the front side and the vegetation mats are on the fill side.

5.First layer of fill material rolled out and roller compacted

- - Roll out and roller compact the first layer of fill material up to the flex joint attachment position of the first layer (finished 1-layer thickness: approx. 25 cm).

6. Attachment of first level flex joint, chain and pressure plate

- - Insert the flex joint into the vegetation mat and bolt the chain and flex joint together.

- - Chain is laid perpendicular to the walls.

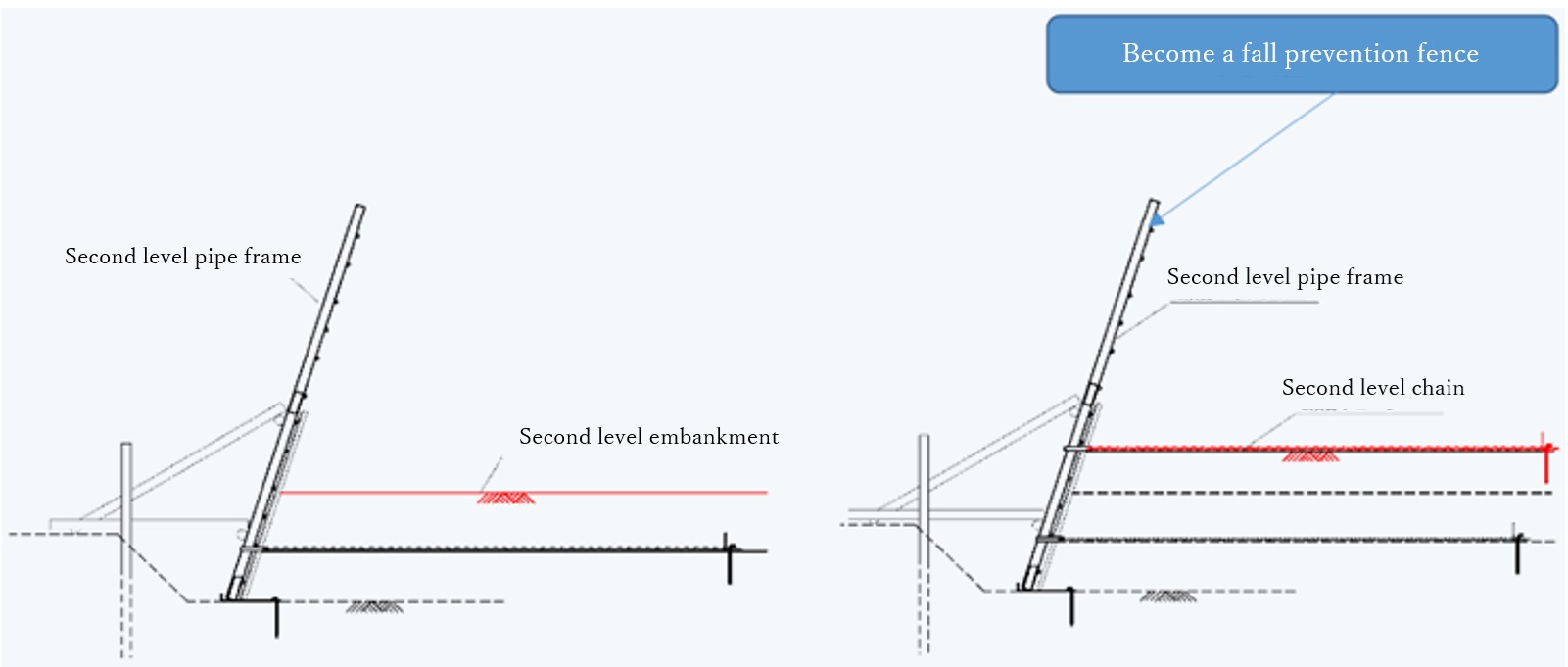

7.Second layer of fill and installation of second layer of pipe frame

- - Rolling out and roller compacting the second layer of fill material.

- - Install second layer of flex joint about 50 cm above the first layer, and connect it to the chain and pressure plate.

- - The same procedure is repeated thereafter.

8.Top rail installation

- - Cut the walls to match the finished longitudinal slope, and rust-proof the cut surfaces.

- - Insert the top rail and tighten the bolts.

- - Fill material is placed up to the top edge, roller compacted and completed.

After completion

Revegetation status

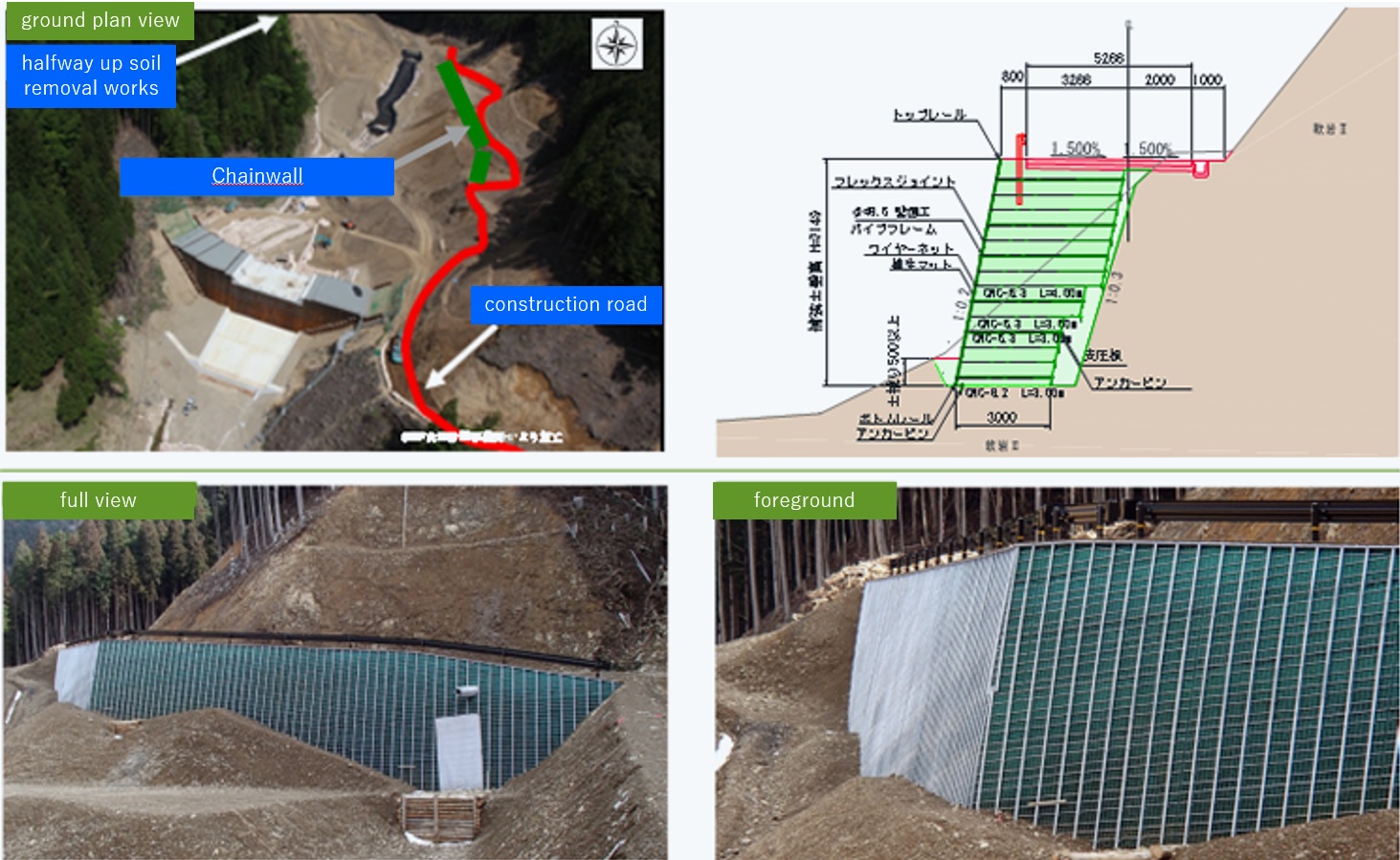

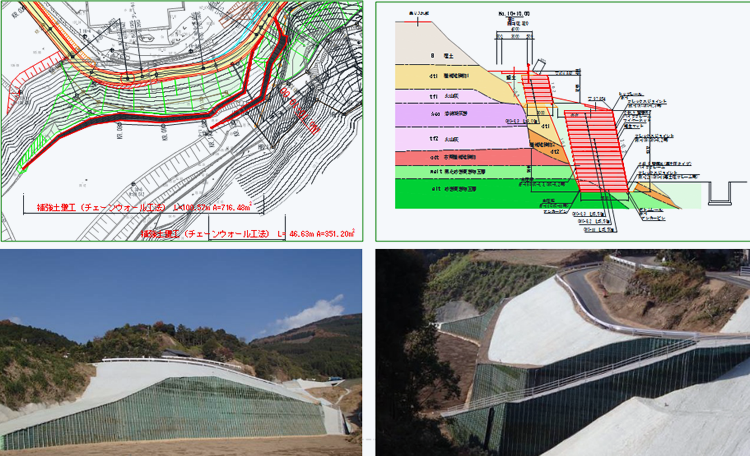

Construction results Ministry of Land, Infrastructure, Transport and Tourism results

- - Office: Kii Mountain Erosion Control Office, Kinki Regional Development Bureau, Ministry of Land, Infrastructure and Transport

- - Construction scale: A=494.7m2 Hmax=8.0m

- - Project name: 2014 Kitamata area weir and other works

- - Contractor: Kumagai Corporation

- - Office: Ministry of Land, Infrastructure, Transport and Tourism, Kyushu Regional Development Bureau, Nobeoka Office of Rivers and National Highways

- - Project name: Miyazaki 218 Hase Area Improvement Works

- - Project name: Disaster restoration work on village forest roads: Forest Road Matsuhashira Line

- - Office: Totsukawa Village, Yoshino-gun, Nara Prefecture

- - Construction name: West Kamitake trunk line (West Gunma Shibukawa) new construction (2 sections).

- - Construction management office: Nakanojo Office, West Kamitake Trunk Line, Transmission and Substation Construction Centre, Engineering Department, Tokyo Electric Power Co.

- - Construction name: East Kyushu Road (between Kiyotake and Kitago) Inoyae Tunnel North No. 3 construction road works.

- - Office: Miyazaki Office of Rivers and National Highways, Kyushu Development Bureau, Ministry of Land, Infrastructure and Transport

- - Project name: Matsunozaka branch line disaster recovery work on Shiiba Forest Road.

- - Miyazaki Northern Forest Office, Kyushu Forest Office, Forestry Agency

Construction examples of thinned timber specification

- - Construction name: Kikan (Nichi) No. 1-1 Forest road establishment work.

- - Office: Forestry and Forestry Division, Industry and Economy Department, Nanyo Regional Bureau, Ehime Prefecture

- - Project name: Kikan (extend) No. 1-1 Forest Road Establishment Work

- - Office: Forestry and Forestry Division, Industry and Economy Department, Nanyo Regional Bureau, Ehime Prefecture.