Kagomaru-kun®

(large cylindrical wire mesh)

- NETIS: KK-160001-A

- Japanese Patent No. 6203671, 6272261

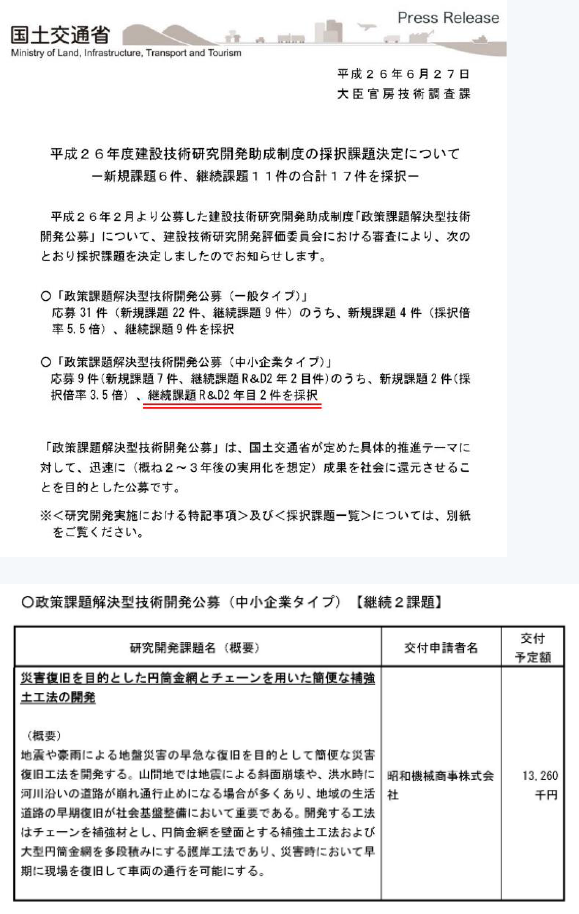

- Construction method adopted by the Ministry of Land, Infrastructure, Transport and Tourism's Construction Technology Research and Development Subsidy Program

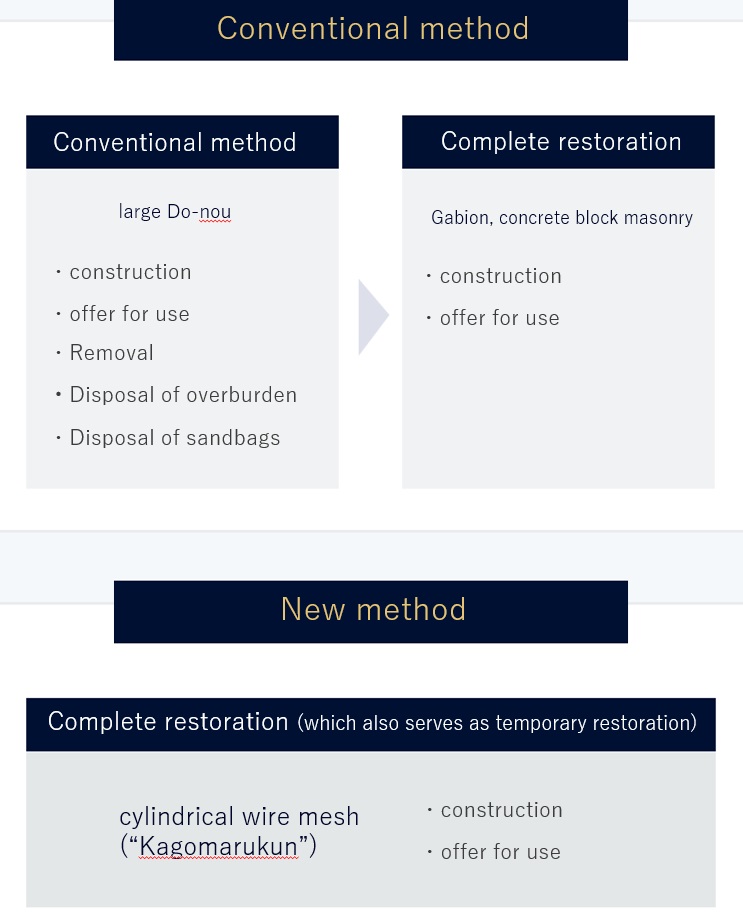

Larger cylindrical wire mesh cage focused on restoring revetment and mountain slopes

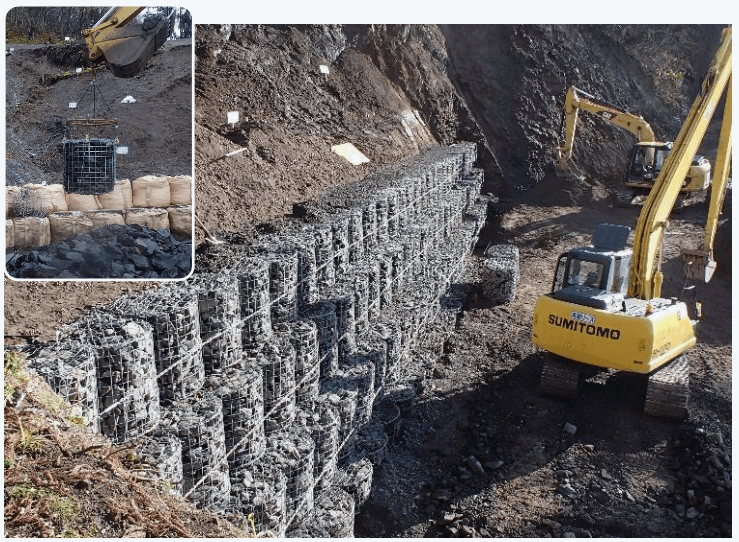

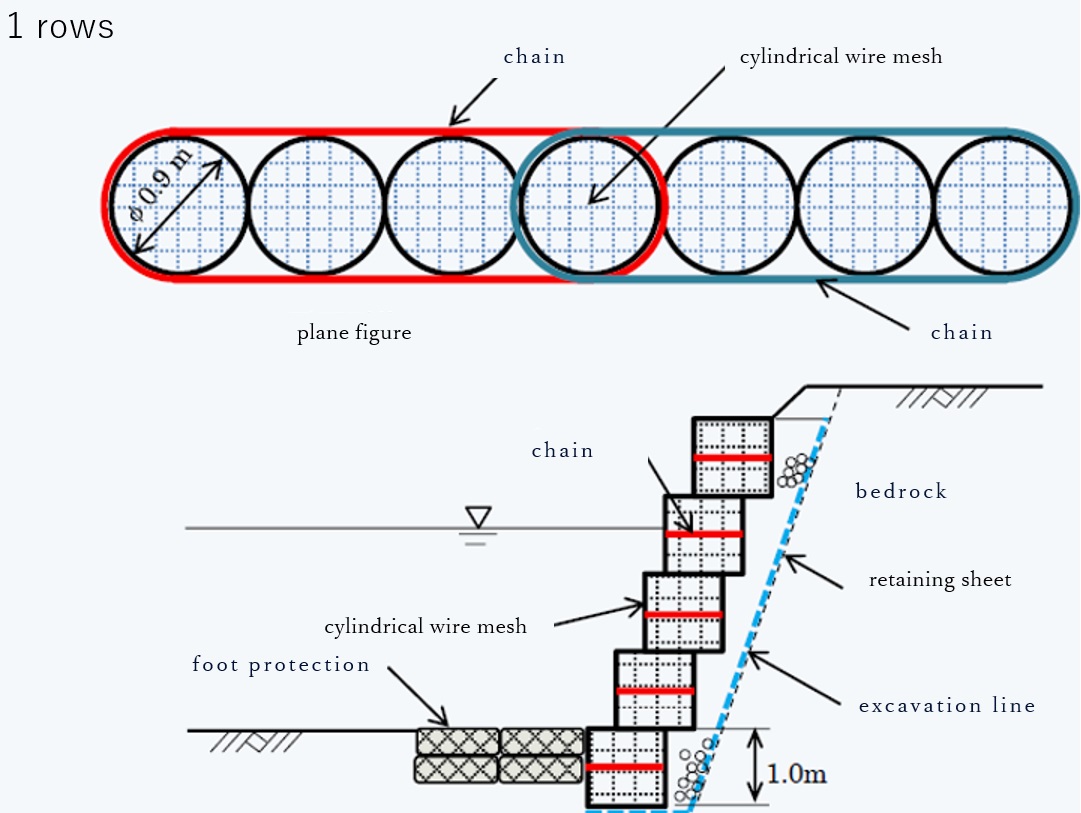

Can be assembled on land before installation

Hmax = about 8m (earth retaining wall)

Kagomaru-kun is a construction method developed under the Ministry of Land, Infrastructure, Transport and Tourism's Construction Technology Research and Development Subsidy Program.

This method has been adopted for three consecutive years since 2012!

Features of Kagomaru-kun

Faster and more reliable restoration

- - Less bulky (semi-cylindrical wire mesh is carried to the site in a stacked condition)

- - Easy to assemble

- - The Kagomaru-kun does not collapse, so it can be mechanized for filling rubbles

- - The Kagomaru-kun can be hoisted with a crane, which speeds up the work

- - High stability because the Kagomaru-kun is tied with a chain

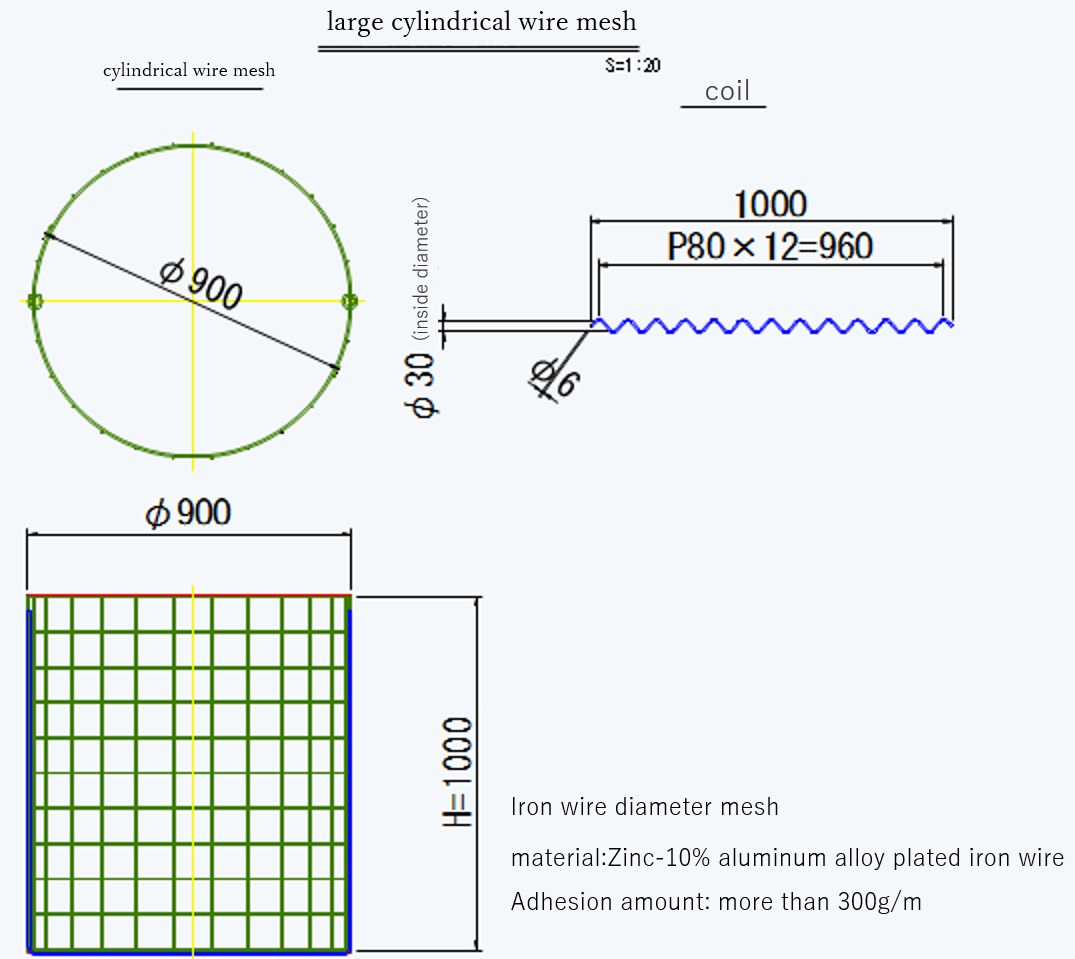

- - Excellent long-term durability

- - Pre-plated welded wire mesh with zinc-10% aluminum alloy plating (more than 300 g/m2) iron wire is used. It has approximately twice the corrosion resistance of ordinary zinc plating with the same amount of adhesion.

- - Construction record: 833m2 (as of March 2016)

Main applications

- - Restoration of river revetments

- - Restoration of slopes in mountainous areas

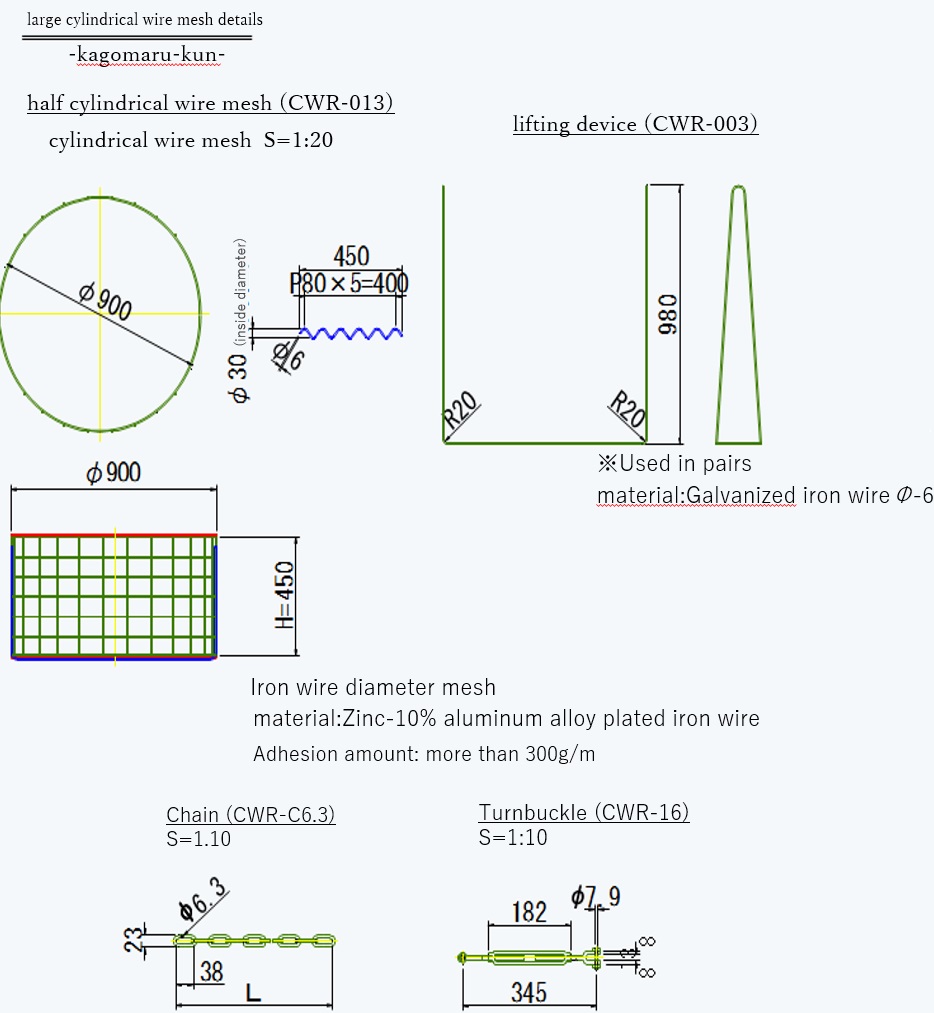

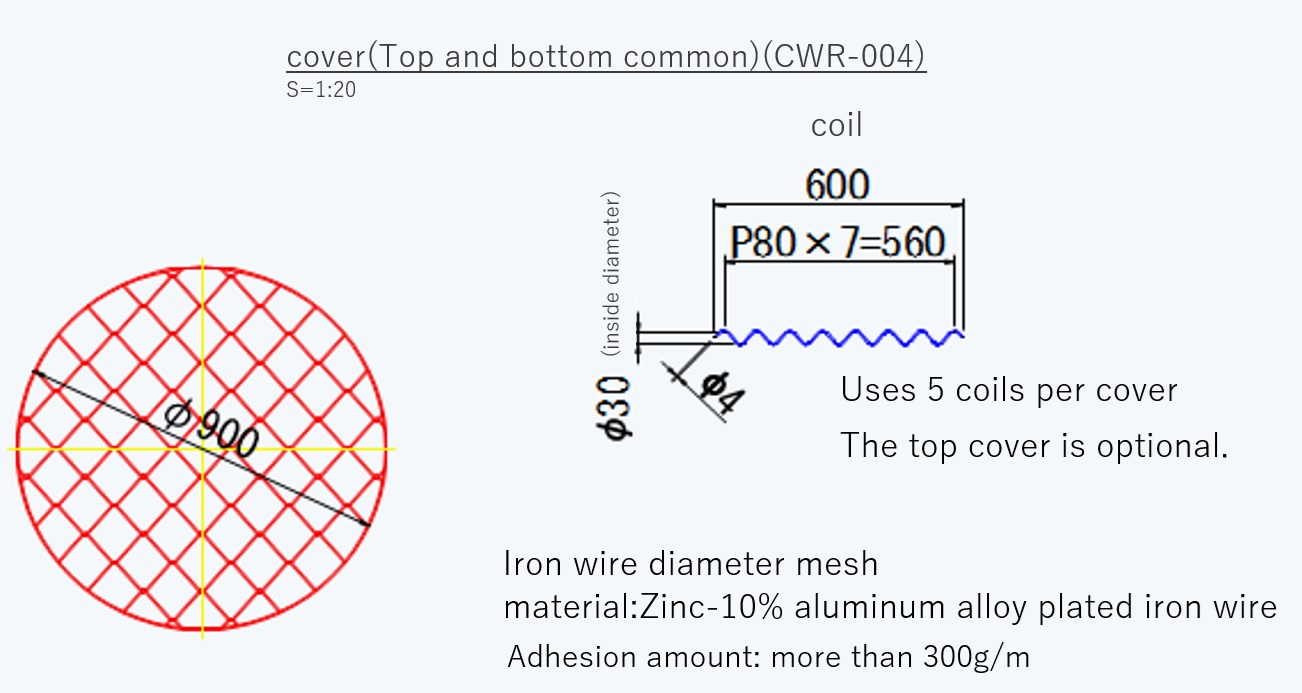

Components of Kagomaru-kun

Structural properties of Kagomaru-kun

Excellent long-term durability

The main body of Kagomaru-kun uses a pre-plated welded wire mesh with zinc-10% aluminum alloy plating (300 g/m2 or more) iron wire. It has approximately twice the corrosion resistance of ordinary zinc plating with the same amount of adhesion.

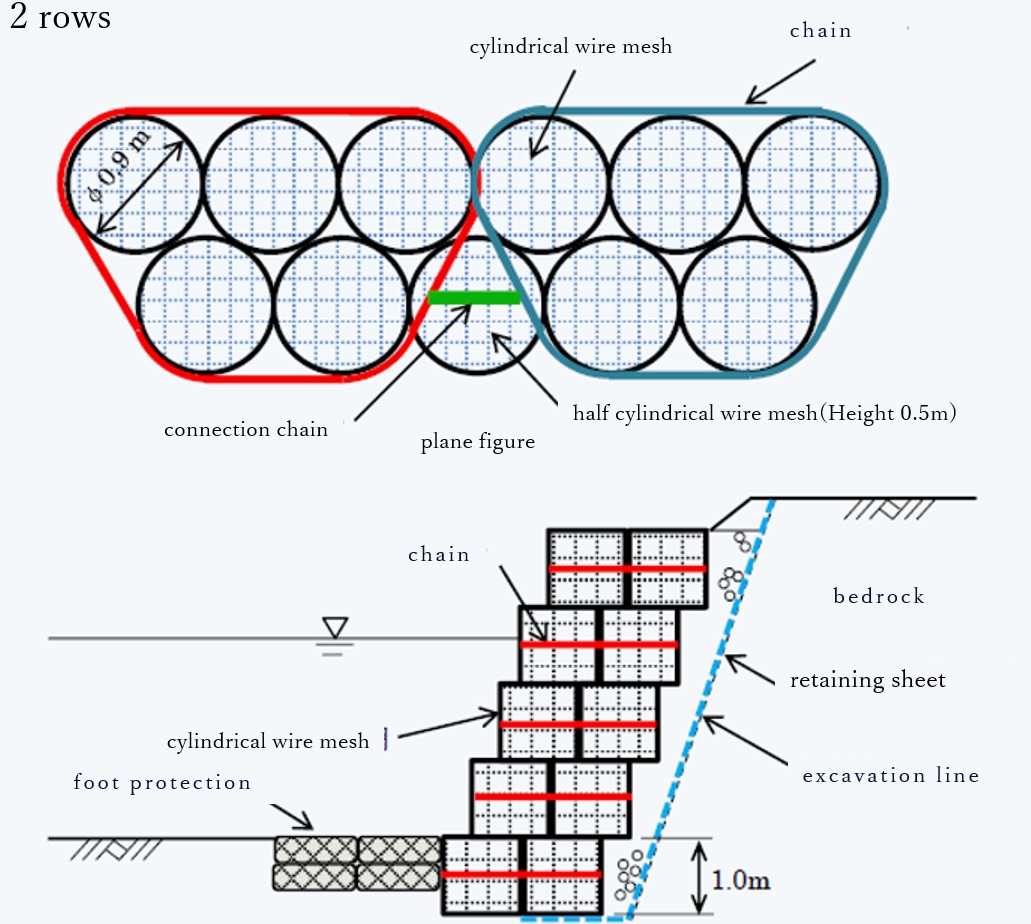

Basic Shape

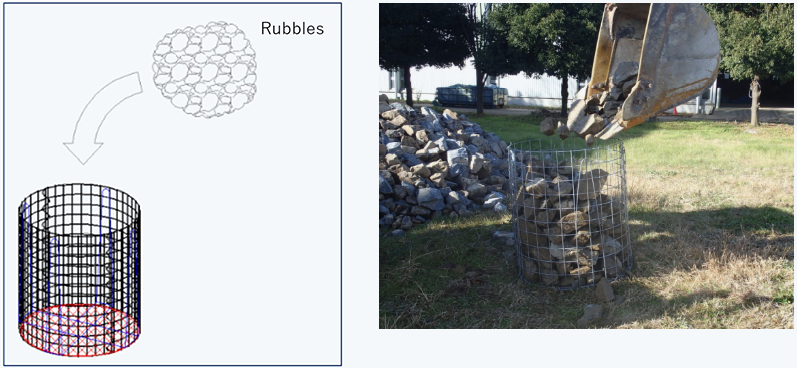

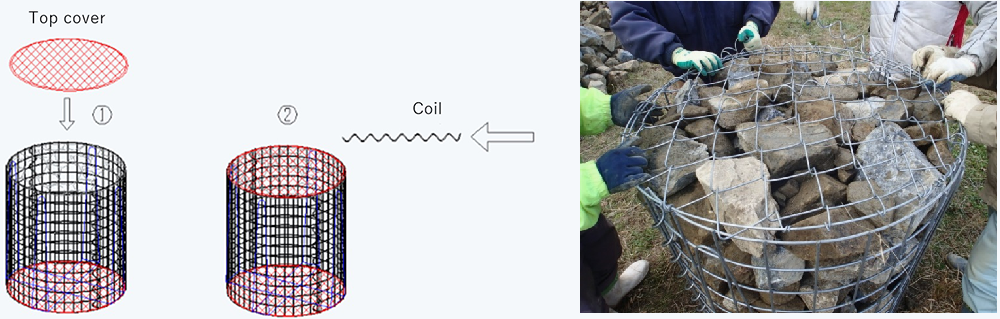

Kagomaru-kun installation procedure

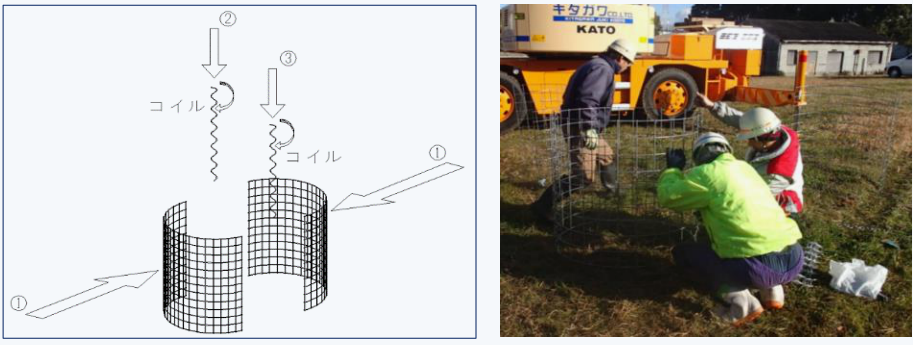

1. Connecting cylindrical wire mesh by coils

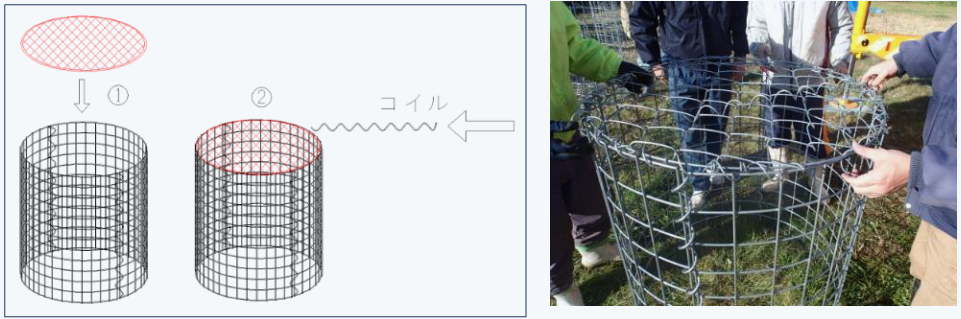

2. Fix the bottom cover with the coil (iron wire diameter φ4 mm).

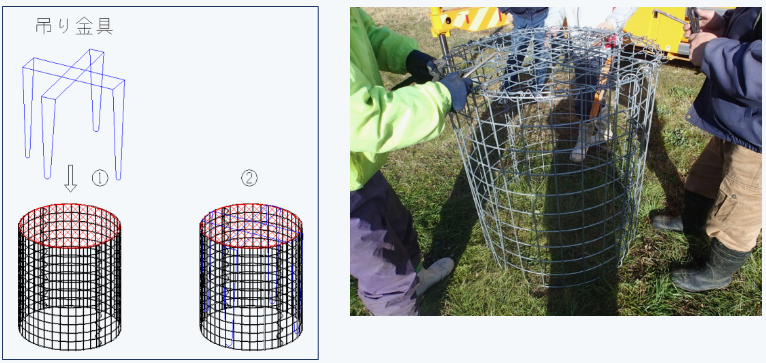

3. Installation of lifting fittings

Attach the lifting bracket about 20 cm away from the coil at the connecting part

4. Putting in rubbles

After putting in the rubbles, lift them up and drop them lightly to the ground to reduce the void space.

5. Manually adjust the top surface of the rubbles.

6. Attach the top cover using a coil (iron wire diameter φ4 mm).

7. Installation and chain tying

Example of Kagomaru-kun construction (1)

- - Project name: New construction of Zainokami forest road (dedicated forestry road) in 2014

- - Office: Akita Forest Office, Tohoku Forest Management Bureau, Forestry Agency

- - Scale of work: A=118.8m2 H=5.0m (bottom two rows)

- - Summary: During excavation, earth collapsed in the newly constructed section of a dugout forest road. The collapsed areas were repaired by counterweight fill with Kagomaru-kun.

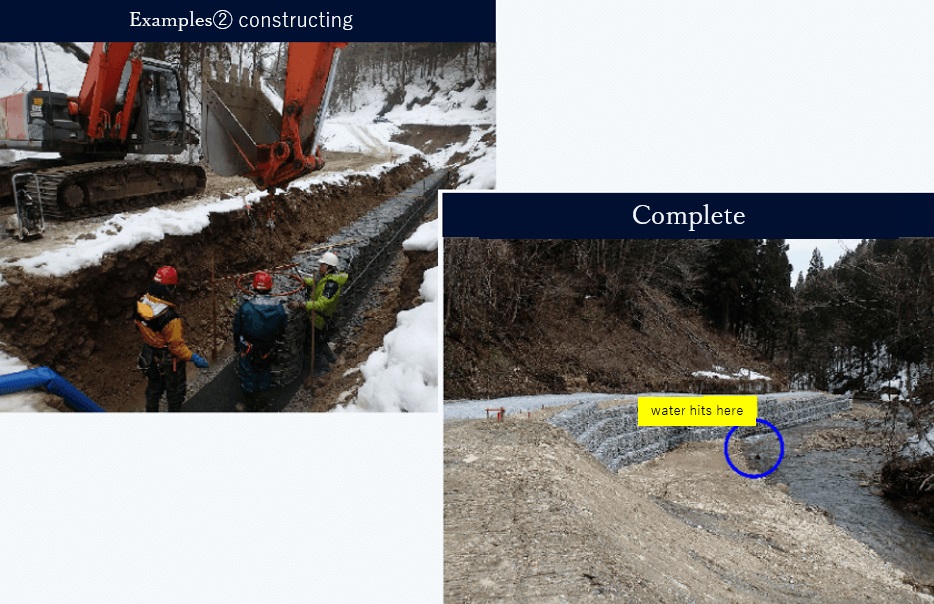

Example of Kagomaru-kun construction (2)

- - Project Name: Shinsawa Forest Road Disaster Recovery Work

- - Office: Yoneshiro East Forest Office, Tohoku Forest Management Bureau, Forestry Agency

- - Scale of work: A=118.8m2 H=5.0m

- - Summary: The original design called for block piling, but the ground collapsed during excavation at another location, so the Kagomaru-kun was adopted as a safe method of construction.

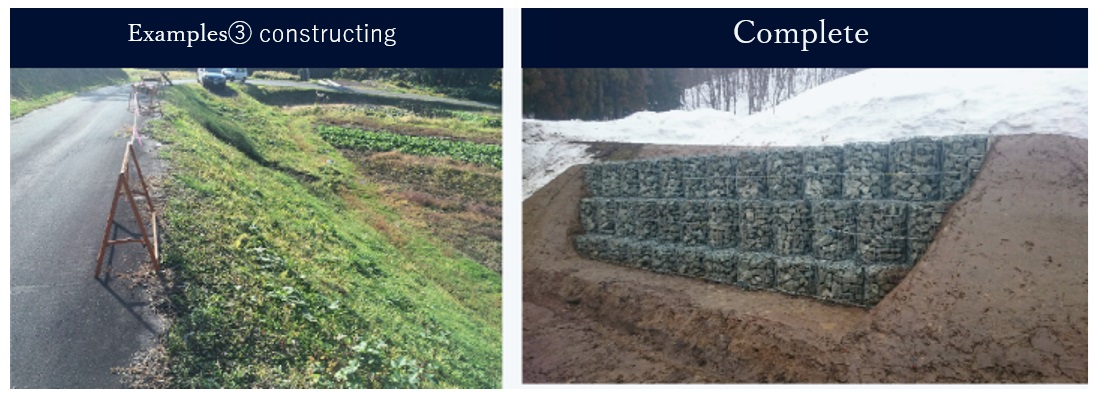

Example of Kagomaru-kun construction (3)

- - Project Name: Forest Road Kodaira Line Road Collapse Restoration Work (Section 1)

- - Office: Oishida Town Office, Kitamurayama-gun, Yamagata Prefecture

- - Scale of work: A=32.4 m2 H=3.0m

- - Summary: The roadside is a field and the ground is clayey soil. The road embankment became a waterway and the slope collapsed. The pavement surface is also cracked. In order to ensure permeability and bearing capacity, we planned to use a recycled crusher run 50 cm below the foundation.

Example of Kagomaru-kun construction (4)

- - Project Name: Sumaki Forestry Dedicated Road Installation

- - Ordering office: Fukushima Forest Office, Forestry Agency

- - Scale of work: A=20.7m2 H=2.0m

- - Summary: Earth retaining for the landslide area where cracks occurred on the slope. Root consolidation work was planned using rubble collected at the site.