Reinforced Soil Wall Forestwall

- Japanese Patents: Name "Reinforced soil walls", - Japanese Patent No. 5770330, 5833329

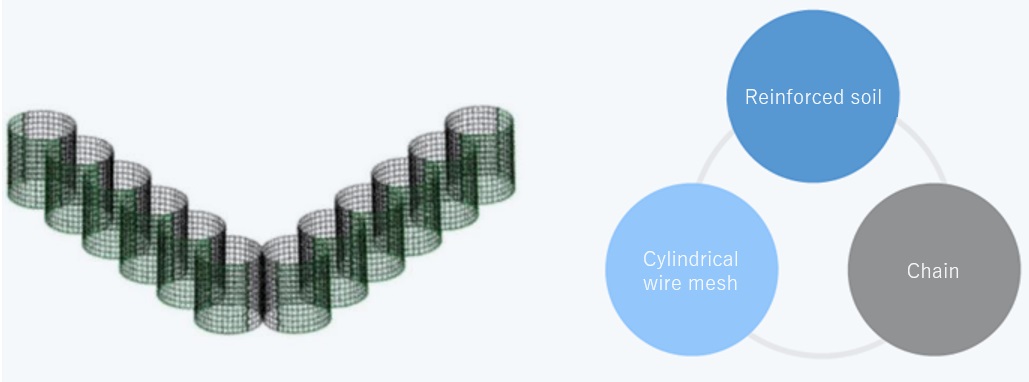

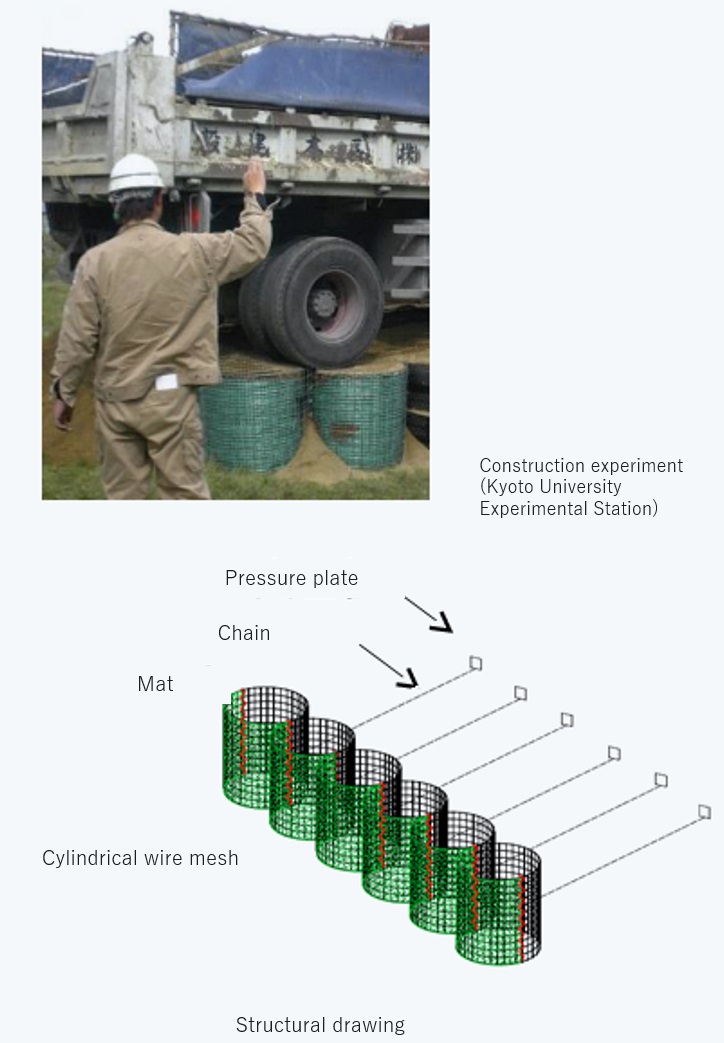

Reinforced soil wall construction method with improved workability by using lightweight, easy-to-assemble and flexible cylindrical wire mesh. Ideal for restoration of slope disaster. Hmax = about 5.0m

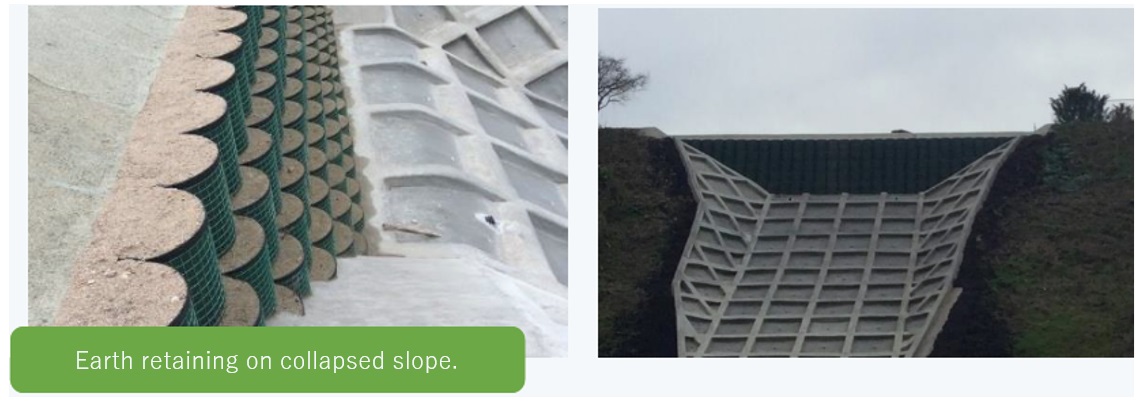

Kanto Regional Forest Office Fukushima Forest Office Tambatateyama Forestry Dedicated Road New Construction

Features of Forestwall

Main applications

- - Road network maintenance of forest roads and forestry roads

- - Slope disaster restoration

Structural properties

- - Stability and high load-bearing capacity (cylinders of the same level are connected by special coils)

- - Excellent long-term durability, same as Kagomaru-kun.

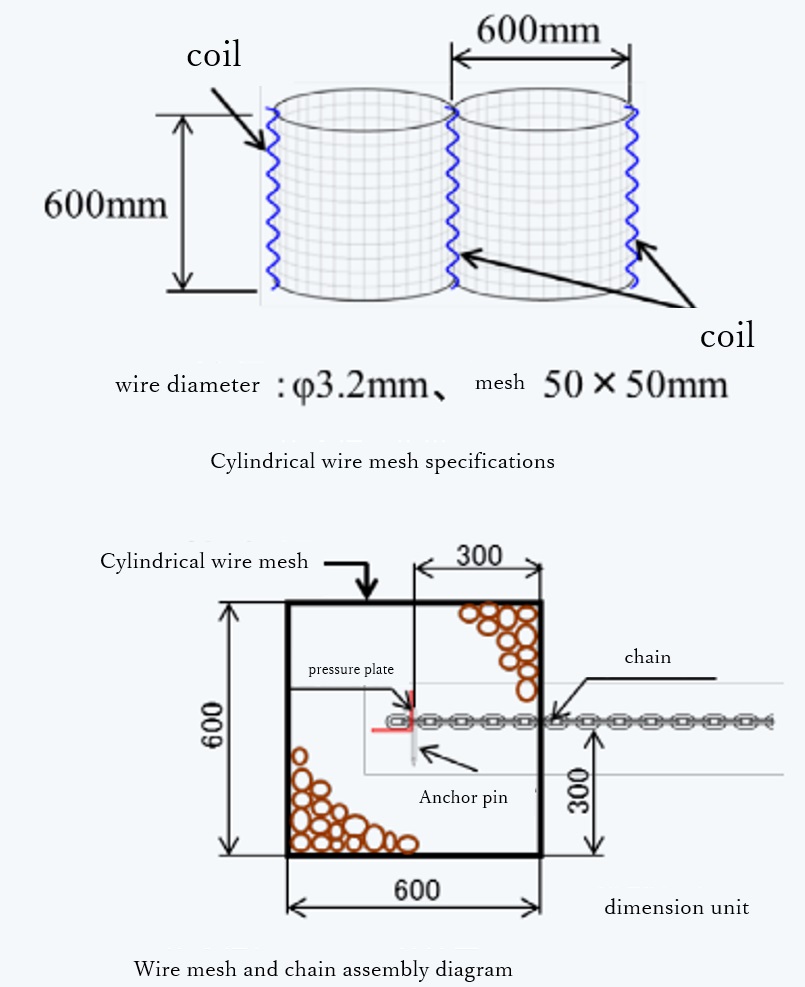

- - Pre-plated welded wire mesh with zinc-10% aluminum alloy plating (300 g/m2 or more) iron wire (φ3.2) is used. It has approximately twice the corrosion resistance of ordinary zinc plating with the same amount of adhesion.

Ease of Construction

- - Easy to assemble (components are semi-cylinders, coils, mats, chains, support plates, and anchor pins)

- - Fast installation (cylinders are self-supporting, so no fixing members are needed during installation)

- - Lightweight components (cylindrical wire mesh: 2.8 kg/piece, coil: 0.2 kg/piece)

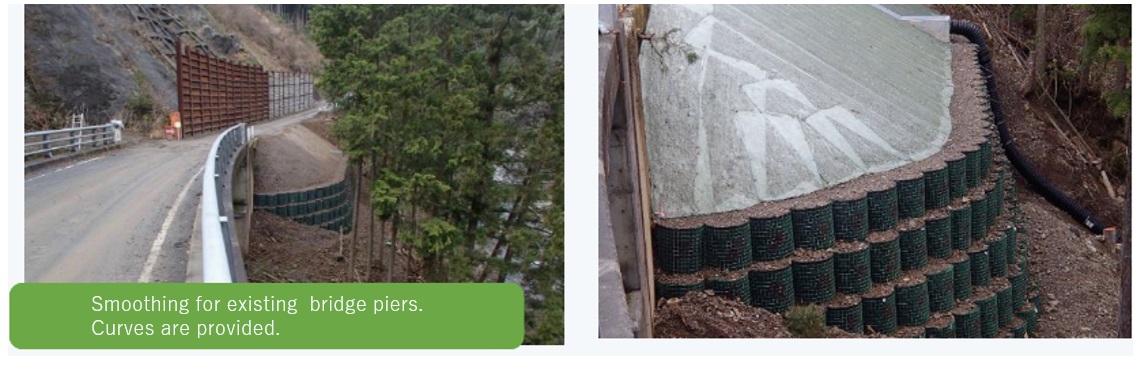

- - Curved lines and broken points can be constructed by arranging the cylinders in different ways.

- - High degree of freedom in on-site response, such as changing the shape according to the topography

- - Less bulky (semi-cylindrical wire mesh is carried to the site in a stacked condition)

Economical

- - Low cost (material cost is reduced by 50% compared to chain wall)

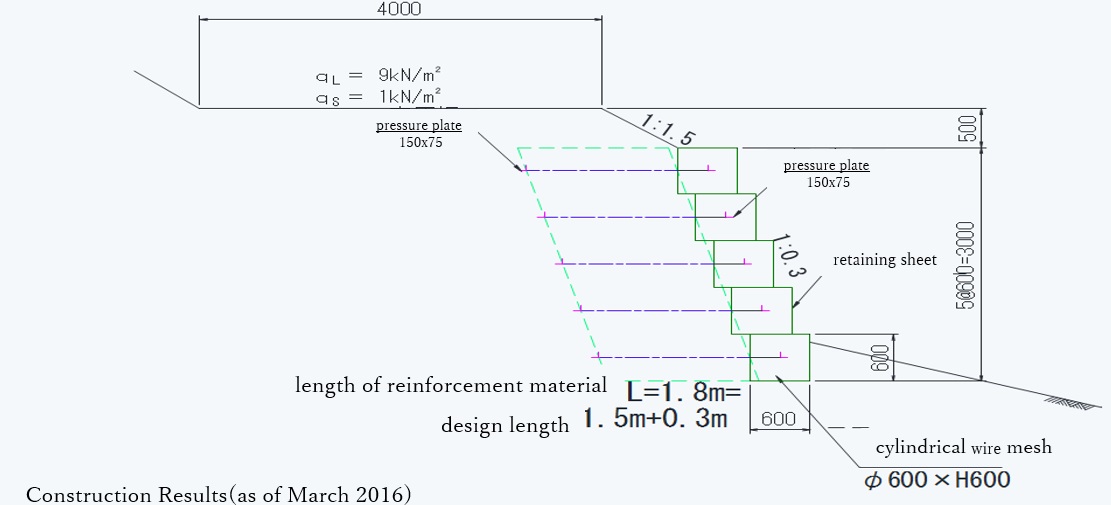

Forestwall Standard Cross Section

Main applications

- - Road network maintenance of forest roads and forestry roads

- - Slope disaster restoration

Cylinders restraining soil have high load-bearing capacity

Forestwall Construction Procedure

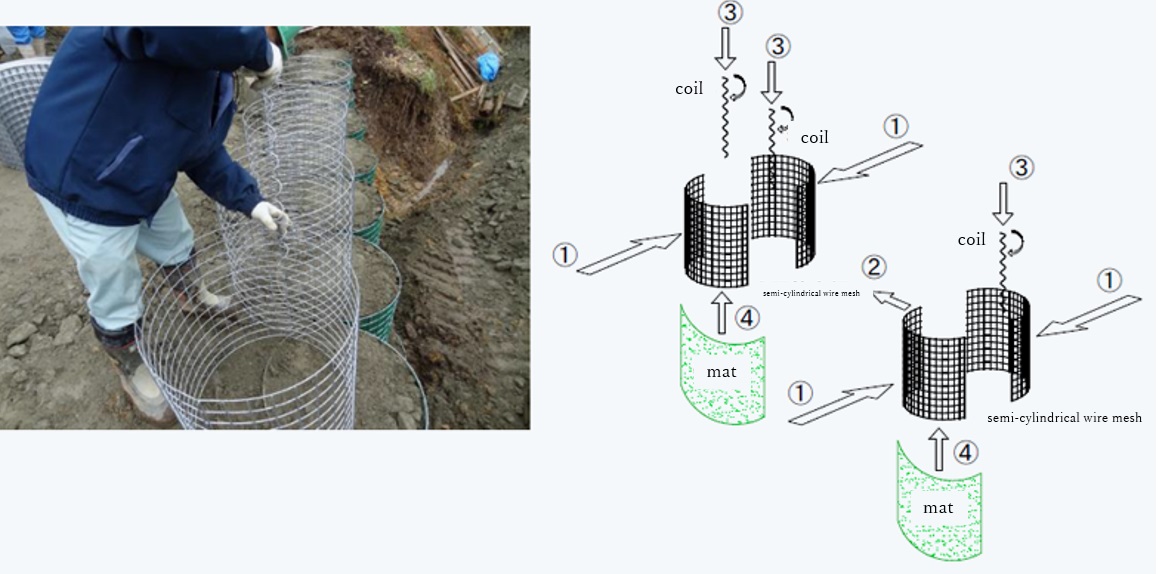

1. Connecting and assembling cylindrical wire mesh with coils

Assemble the cylindrical wire mesh using semi-cylindrical wire mesh and connecting coils.

Next, mats are attached, and soil is spread and compacted to half the height of the inside of the cylinder.

2. Installation of chains and pressure plates

- Chain is installed inside the cylindrical wire mesh.

- Chain and pressure plate are installed in the embankment.

3. Leveling and rolling compaction of fill material

- Spreading and rolling compaction of fill material

- Leveling and rolling compaction of the area near and above the cylindrical wire mesh

Forestwall example of construction

- - Name of work: Tambatateyama Forestry Dedicated Road New Construction

- - Office: Forestry Bureau, Kanto Forestry Administration, Fukushima Forestry Administration, Shirakawa Branch Office

- - Project name: Uenosawa Branch Line Forestry Road New Outer Construction Site (H24 correction) No. 3

- - Office: Kanto Regional Forest Office, Agatsuma Forest Office (Gunma Pref.)

- - Project name: Idegawa Forest Road, Kakidaira Branch Line Outside 2 Improvement Work Idegawa Forest Road (1)

- - Office: Iwaki Forest Office, Kanto Regional Forest Office (Fukushima Prefecture)

- - Project name: Idegawa Forest Road, Kakidaira Branch Line Outside 2 Improvement Work Idegawa Forest Road (2)

- - Office: Iwaki Forest Office, Kanto Regional Forest Office (Fukushima Pref.)

- - Project name: Forest road Koyabugawa line repair work

- - Office: Hidakagawa Town Office, Hidakagawa-gun, Wakayama Prefecture

- - Project name: Disaster restoration work for former Kawamoto Nishi Elementary School in 2013

- - Office: Kawamoto Town Office, Ochi-gun, Shimane Prefecture